Completely clean the sealing area and remove any dirt, corrosion, oil or leftover from old gasket material.

Cut one ending of the Expanded PTFE Joint Sealant tape and remove just a little of the protecting paper. Place the tape at the nearest possible position next to the bolts, starting next to a bolt hole. Fit the gasket around the entire flange circumference and across the endings as shown in figure 1.

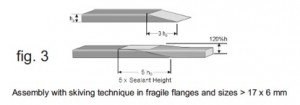

Assembled in fragile flanges apply techniques as shown in figure 2. Skive the endings as shown in fig. 3 and overlap according to the recommended overlap length. Cut off the excess, tapering to the end, leaving a total thickness of approx. 120 %.

At least 4 progressive torque sequences with a torque wrench, in a star of 180° (fig. 1), should follow the first torque by hand.

Finally, perform a circumferential torque check and ensure that the expanded PTFE sealing tape is firmly and durable.